Our Products

COAL TAR ENAMEL

Known as hot applied Coal Tar Enamel & Marketed as plasticise pitch conforming to BS-4164/02 & AWWA-C-203/07 & IS 10221/82 or any such International standard and as per customer's specification.

Use : For protection of underground & aboveground gas, Oil & Water pipelines from corrosion particularly cross country pipelines.

Packing: Light weight M.S. Drums of 50 Kg., 200 - 250 Kg. and bricks/cake form.

SYNTHETIC PRIMER TYPE B

Fast drying Chlorinated Rubber based synthetic Primer having Compatibility with hot applied Coal Tar Enamel conforming to BS4164/02 &AWWA- C203/07.

Use : For Priming of underground & aboveground Gas, oil & water pipeline to provide effective bond between Metal pipeline & Subsequent hot applied coal Tar Enamel.

Packing : 20 Liter and 200 Liter M.S. Drums.

COAL TAR PRIMER TYPE A

Slow drying Coal Tar based primer, preparation having compatibility with hot applied Coal Tar Enamel, Conforming to AWWA- C203 and IS 10221/82.

Use : For priming of underground & aboveground Gas, Oil & Water Pipelines to provide effective bond between metal pipe with subsequent hot applied coal Tar enamel.

Packing : 20 Liter and 200 Liter M.S. Drums.

COAL TAR PRIMER TYPE “C”

Two Component heat curable liquid epoxy primer. This primer Uses latent heat of the hot enamel / Hot applied Tape to give bonding between Metal & Coal Tar Enamel or Tape conf. AWVVAC — 203.

USE:- for Underground or above ground Oil / Water Pipelines protection & provide effective bond between Tape & Metal Pipelines.

Packing : 20 Ltrs.

COAL TAR IMPREGNATED OUTER WRAP

Non woven glass fiber mat impregnated with modified and plasticized Coal Tar or Bitumen as per AWWA C-203/07 and IS : 10221-1982 Outer wrap is dusted with fillers to prevent the layers from sticking together in the roll form.

Use : Provides mechanical strength to C.T. Enamel coatings for Pipeline Protection.

Packing: 150 mm to 500 mm width X 200 Mtr. length packed in corrugated boxes & wooden cases.

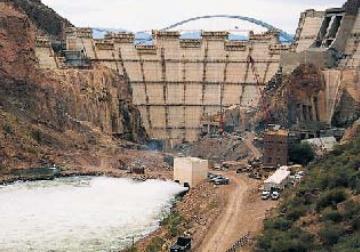

Porwal ‘s Mastic HD

Coal Tar based thixotropic nature thrust resistant ready to cold apply Coal Tar enamel. It has better compatibility with one coat of coal tar based primer to get desired performance. Coal Tar based product confirming to CA-50 and SSPC 33 paint specification.

Use : or painting of Dams and Canal gates, inside steel pipes & Structures.

Packing : 20 Kg. M.S. drums.

PORWAL'S COAL TAR TAPE

Coal Tar based hot applied anti corrosive tape wrap. High tensile strength fiber glass fabric impregnated and dipped in coal tar enamel and saturated as per AWWA C-203/07, IS 1537-03/IS 10221-07.

Use : For protection of underground & above ground gas, Oil & Water pipelines.

Packing : 250/333/500/1000 mm width and standard length of 10/15/20 Mtr. and also supplied according to pipe dia. Thickness 1.5/2.0/2.5/3.0/4.0 mm.

TAPE PRIMER

Tape Primer Type "B" Conf. IS 15337 &AWWAC-203

Slow drying Rubber base Coal Tar Primer having compatibility with hot torched Coal Tar Tape conf. to AWVVAC-203, IS-15337 - 03 & IS -10221-07.

Use : For Underground or above ground Oil/Water Pipeline protection & provide effective bond between Tape & Metal Pipelines.

Packing : 20 liters & 200 liters.

BLACK JAPAN / BASE PRIMER

Cold applied anticorrosive paint resistant to acids & alkalies. Base primer prior to application of tape primer on blasted M.S. surface.

Use : For protection of Iron and Steel structures, Pipes and other construction above or below water.

Packing : 25 Ltr. Tin, 20 Ltrs. & 200 Ltrs. M.S. drums.

COAL TAR PITCH MODULATE

Modified Coal Tar Pitch blended with fillers as per AWWA- C-203 .

Use : Suitable for manufacture of Coal Tar impregnated Glass Fiber outer wrap for pipeline protection.

Packing : Light weight M.S. Drums of 200 Kgs.

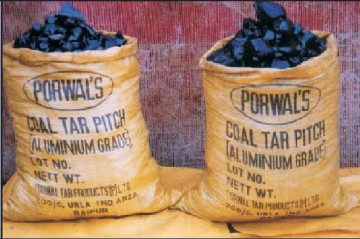

COAL TAR PITCH

Quality Pitch manufacturer by unique Hi-Tech process of its kind in India with high Beta resin & high Cooking value to feed requirements of different Indian Industries like... Aluminum grade, Graphite grade, Electrode Grade, Foundry Flux Grade & Carbon Paste Grade.

Use : Manufacture of Roof binder, Refractory Bricks, Battery Industries, Pitch Fibres Pipes, Fireworks and in blast furnaces !addle repairs etc.

Packing : 50 Kg. H.D.P.E. Bags, 200 Kgs. M.S. Drums & Liquid in self heated insulated tanker.

NAPTHALENE DISTILLED

Off white to light brown colour having crystallizing point 78.5°C in lumps/powder form.

Use : Manufacture of Dye-Intermediates, H-acid, Beta Naphthol dispersing agent for Chemical formulation for Leather finishing.

Packing : 50 Kg. H.D.P.E. bags.

NAPTHALENE REFINED / BALLS

Snow white color having crystallization point 79°C in powder/balls/bricks form.

Use : Insecticides as preventive for moths and balls for woolen clothes.

Packing : 50 Kg. plastic laminated jute bags.

LIGHT CREOSOTE OIL

Coal Tar base high boiling oils as per IS Specification.

Grade 1 With TarAcid 8% to 10% .

Grade 2 With TarAcid 30% to 35%.

Grade 3 Without TarAcid.

Use : For manufacture of Phenyl, Carbon black feed stocks.

Packing : 200 Kg.M.S. drums and loose in Tanker.

HEAVY CREOSOTE OIL

SCoal Tar base high boiling oils as per IS Specification 218 well known as a wood preservative oil.

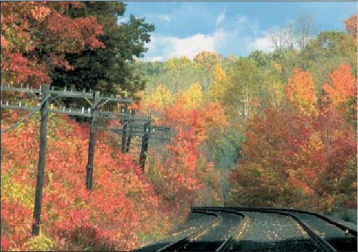

Use : For wood preservative and carbon black feed stocks and Railway Sleepers.

Packing : 200 Kg. M.S. drums and loose in Tanker.

ANTHRACENE OIL

High boiling Coal Tar oil procured during distillation of crude Coal Tar.

Use : Excellent material as a feed stock for Carbon black and for manufacture of coal tar enamel.

Packing : 200 Kg.M.S. drums and loose in Tanker.

TAR ACID & CRESYLIC ACID

Coal Tar Based Natural Acids derived from Tar having distillation range between 180°C to 250°C. and 200°C to 210°C.

Use : For disinfectants, Cable enamels, Leather preparations, Insulating varnishes and other chemical formulations.

Packing : Available in sound M.S. drums 200 Liter.

COAL TAR (DEHYDRATED/P.D./RECONSTITUTED)

High temperature & Low temperature Coal Tar dehydrated, reconstituted and partially distilled to feed the requirement of different Industries.

Use : Manufacture of Coal Tar Epoxy paints, Carbon black, Pitch recovery of other Tar Products and as fuels.

Packing : 200 Kg.M.S. drums and loose in tanker.

COAL TAR FUEL

Coal tar fuels are derived by the carbonization of Indian Coals having low Sulphur contents and high Calorific value after removing low calorific contents.

Use : Asa furnace oil.

Packing : 200 Kg.M.S. drums and loose in Tanker.

SOLVENT 1519 / 2060

Petroleum based or coal tar oil based high aromatic solvents of different boiling range. Aromatic contents as per customer's requirements.

Use : Manufacture of Paints, Printing inks, pesticides etc.

Packing : 200 liter M.S. drums and loose in Tanker.

SOLVENT NAPHTHA

A Coal Tar distillate 90% distils upto 220°C. 100% aromatics with or without Phenol and pyridine impurities.

Use : Suitable for manufacture of Paints.

Packing : 200 liters M.S. drums.

COAL TAR EPOXY PAIN

Coal tar epoxy paint Part 'A' and '13' are mixed prior to application. A heavy duty high build Porwal's CT epoxy coatings for the protection of steel and concrete immersion service can be applied in thickness upto 50-300 Microns per coat. Conforming to IS -14948-2001.

Use : Long-lasting epoxy coating of Marine ships, Pipelines and Steel structures.

Packing : 20 Ltrs in two part M.S. drums.

ZINC PHOSPHATE PRIME

Epoxy Zinc Phosphate Primer Part "A" & Part "B" mixed prior to application. An economical lead free epoxy primer has excellent physical properties and good all around chemical resistance can be applied at thickness upto 40-200 microns per coat. Conforming to IS-13238.

Use : Protection of structural steel, concrete equipments and tank exteriors etc.

Packing : 20 liters in two part M.S. drums.

ZINC RICH PRIMER

Two pack Polyamide cured epoxy Resin based Zinc Rich Primer to give 90% Zinc content in dry film. It has excellent protection to Steel Structures, Tank, Pipelines, Plant & Machinery. It also provides cathodic protection & compatible with a wide range of top coats. Conforming to IS-14589.

Use : A superior zinc rich primer for protection of refineries, power plants, petrochemical units, fertilizer units, pen stock, sluice gates etc.

Packing : 20 liters in two part M.S. drums.

ALUMESTIC EPOXY

High build, modified aluminum epoxy mastic. Part 'A' & 'B' mixed prior to application. Self priming coating with excellent adhesion to Rusted steel & most aged paints. No top coat is required.

Use : Recommended for repainting rusty steel and for upgrading old, deteriorated coatings. Ideal for metal buildings, piping, process equipments, highway bridges and exposed steel etc.

Packing : 20 liters in two part M.S. drums.

ACRY POLYURE

Aliphatic acrylic Polyurethane. Part 'A' & Part 'B' are mixed prior to application. This is glossy tile like attractive top coat with weathering resistance & color retention. Can be used on primed surfaces. Conforming to IS 13213-1991.

Use : Porwal's acrypolyure is an excellent coating for use in chemical processing, pulp and paper, petrochemical and similar demanding industries also recommended for heavy marine, institutional and waste treatment and offshore drilling industry.

Packing : 20 liters in two part M.S. drums.

EPOXY POLYURE

Blend of Modified Epoxy Polyurethane. Part 'A' & Part 'B' are mixed prior to application having flexible properties. Can be applied on primed surface of metal or Cement. Used for protection of steel surfaces from Chemical or Salt rich atmosphere.

Use : It provides very effective moisture barrier protection. Used as an exterior coating for industries.

Packing : 20 liters in two part M.S. drums.

FOOD GRADE EPOXY

A Two component, light colored, solvent free pure epoxy coating Confirming to BS-6920 & IS:3589-2001 & AWWA-C-210 & Tested as per ASTM procedures. To be applied by spray / brush &to give desired D.F.T.

Use : Recommended for potable water pipelines and containers, ship ballast tanks, void spaces, cofferdams and wet spaces. etc.

Packing : 20 liters in two part M.S. drums.

HOT SEALING COMPOUND

Coal tar based polymerized joint sealing compound to be applied in hot stage most suitable for heat and blast resistant. Resistant to petroleum products and oils.

Use : Suitable for air runways, Railway platforms, flooring for large Industrial sheds and road construction.

Packing : 25 Kg. M.S. drum.

RED OXIDE PRIMER

Red Oxide Primer is based on anti Corrosive resins and red oxide powder. It conforms to IS : 101-1979. Red Oxide Primer is an easily applicable anti-Corrosive primer recommended for protecting Iron, Steel and Ferrous Metal surface.

Use : It is recommended for protection iron, steel and ferrous metal surface Red Oxide Primer acts as a prime coat for fresh surfaces or surface to be repainted.

Packing : 20 liters.